[note: the second stage of this experiment is in {slow} progress]

Yes, you read that right. I roasted 50 grams of coffee in a coffee mug. Do not try this at home. Do it at work in the conference room. ;-)

I've been interested in radiant heat roasting, so I've been doing some experimenting in preparation for something more ambitious. Just having fun.

The problem with experimenting is that I'm using small batch sizes, and poor heat conservation is my bane. It just doesn't do to cobble some lame thing together and hope for the best.

With that in mind, I cobbled some lame thing together and hoped for the best.

I started with a premise: it should be possible to roast 50 grams of coffee with 50 watts of halogen power in a sane amount of time.

I also started with a busted stainless steel thermal mug.

Add a 50 watt halogen lamp, a fixture to power it and a piece of corrugated cardboard . . .

...and you have this:

Which gives you this in 30 minutes -- twice what I wish. Dang.

Bad exposure -- they're darker than they look there. I stopped the roast on the fifth snap of second crack -- my reference point for this experimental stuff. It's a wonderfully even roast, smells good, and I'm going to drink it.

Holding it all together with one or two hands while agitating the beans manually was a bit crazy. At any moment I was waiting for the halogen to crack open and the filament to ignite the bean mass. Also, all the chaff was present during the entire roast, which caused a lot of smoke. It separated out easily enough in my cooling tray.

So I'm taking twice as long as I want with 50 watts and 50 grams. I still think it can be done. I lost a lot of steam, heat and smoke as I'd remove the light now and then to shoot the bean temps with an IR gun. I think I'll contrive a jig to hold it together and make agitation easier, listen for the cracks without shooting temps, and see what difference leaving it closed the whole time will make.

Update 1

OK, Mod One. Thanks to a panicked platoon of friends and acquaintances, I am now aware that cardboard can burn. ;-) Thanks to you all, but I assure you -- I can burn down my house quite as well without the help of cardboard. You see, I have children.

But it would have been necessary to replace the cardboard even if there were not some risk of hearing our insurance company's claims processor asking "you were doing WHAT?" You see, the contraption was a royal pain to agitate for the half lame hour this thing still takes to roast its wattage in beans.

I used a 5 oz. evaporated milk can to create an adapter for a new lamp -- a 60 watter but smaller. I use springs for everything I do (you should see me eating Chinese), so I bound it all together with that. Still dangerous, actually, but here's the beast.

This time I tried boiling water -- it did 50 ml (I forgot I was wanting to pair wattage and quantity) in around 14 minutes. That's from a cold mug. With the thing thus preheated, I dropped in 60 grams of beans and powered 'er up. About a half hour later and a puzzled minute into "dang, that doesn't sound like first crack," I realized the smoke I'd been seeing for some time was more than burning chaff, so I terminated my roast and realized I'd done my first Spanish, or somesuch. I had to use it for something, so I tried it. Not bad, for a guy who hates dark roasts. A good Guat. Did it up in a frappe though, so I could use that evaporated milk I'd liberated from part of my new apparatus. Let's hear it for carrageenan, which really gives a great texture!

Agitating this thing is still no fun. It's the old "rotate it, kind of, in an eccentric fashion so that the beans will... bother, that's not quite -- yeah, more like that. Good grief, my wrists" thing. You've heard that complaint a thousand times before though, I'm sure, so I'll not belabor the matter.

Problem: the metal method of mounting the light was not as insulative as cardboard. I'm quite sure I lost a lot more heat through the top this time. Also, this time the bulb was not entirely inside the mug, as before. Although the sides of the bulb never exceeded 300 degrees (I want little by way of conductive heat involved here, you'll recall), it would have been nice to have had that radiance inside the mug so that the air could have been warmed by that, sparing the beans the chore of cooling themselves down for the benefit of the air's comfort. Nuts.

Remember, everything's backwards with radiant heating. The beans are heating the air. The beans are heating the stainless steel walls of the container. Everything's just backwards.

Stay tuned. I'll be turning this thing into a drum roaster, if I can.

Update 2

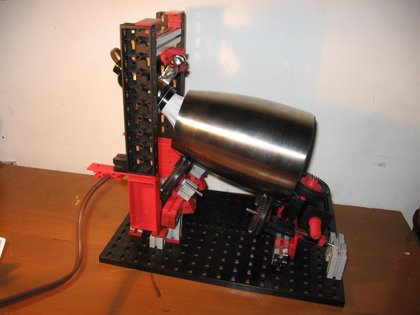

OK, time to turn this thing into a drum roaster. I used Fischertechnik to proto this. If you've never used it, you've missed out on one of the great joys of being a wannabe engineer.

The drum roaster consists of the thermal mug resting on four small wheels, with a thrust wheel on the butt end as well. It rotates well. One of the wheels has a worm drive attached to it (lower right). This will turn the drum. The mess on the left is a gantry to support the halogen light. It needs to be kept in a pretty precise position, partly in the thermos, in order to maximize exposure of the beans to the IR heat.

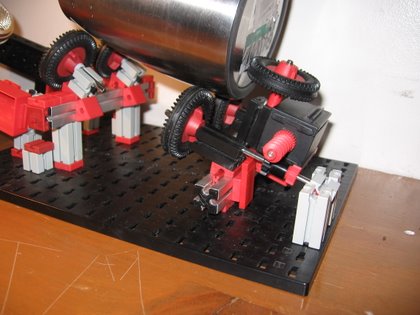

This image shows a better detail of the motor, gears, and wheels:

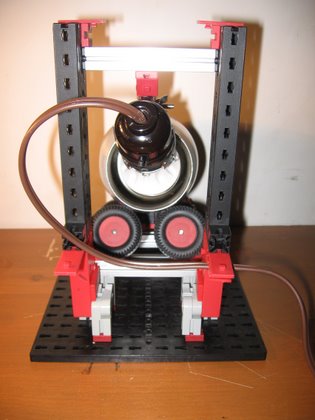

Here's a view of the business end of the drum:

The obligatory side view:

A view of the light. It's coupled to the framework pretty firmly, all things considered. I'd thought I'd have a bit more of a time kludging some jig to keep it in place, but this isn't bad:

And finally, a shot ot the business end with the halogen lamp in roast position.

Finishing the roast should be easy. Drop the gantry, pick up the thermos, and drop the beans into the cooling apparatus.

I wasn't able to find a power supply to run the motor, or I'd have a roast to report. Maybe I can find one tomorrow.

Update 3

Sorry, no roast tonight. Darned busy day, and didn't find time to dig through a pile of old power adapters to find the 9 to 12 VDC unit I need. It'll need to deliver more than the couple hundred mA the one I had on hand does. I used a camcorder battery to turn the drum with some beans after installing the agitator assembly, and had a good laugh at how well it worked. I even engaged the halogen briefly, and was pleased when the beans came out of the unit a bit warm. ;-) Hopefully I'll do a roast on Wednesday.

But a couple pics. I was puzzling how to install some vanes to agitate the beans; they just slide around. I'm wanting to test silicone sheeting, too; I think the friction would do the trick as well as vanes for this particular device. But I wanted immediate gratification tonight and I didn't have any silicone, so thinking quickly, a halogen went on over my head and I came up with this:

Actually, I fussed about with the thing inside the unit and, hamfisted sucker that I am, I bent it up. Then it agitated the beans badly -- the vanes were presenting too much of a profile to the beans. I trimmed 'em so they'd present less surface area, and gave 'em a bit of a twist. But that's not pictured above. However, the spring keeps the vanes in perfect position, and I really like the way the beans agitate now. I think the rotation speed will be fine, provided I provide enough current capacity at 9 - 12 V to keep it going. I don't think my motor will overheat. The axle on my bottom passive wheel wants to wander out of its bushing, so I have a bit of tuning to do on the mechanics yet. That spring also rewarded my dread -- it does capture a few beans. I guess I could wrap some foil around it, but it's darned hard to get fingers into this thing at all, much less be dextrous about it.

Oh, OK -- here's a shot of the final form of the agitator, with some beans to show the scale of this little thing:

Wednesday night I roast! I hope!

Update 4

I'm using a 12V 500mA power supply for the drum motor. It's adequate, but nothing to celebrate. I had to redesign the drive -- the speed of rotation on the first try was preposterous (fast).

As I type this, the roast is proceeding pretty well -- but slowly. The little sucker's a bit noisy, too. [editorial pause] But it made it to second crack in 32 minutes, which was cool. Now I'm only 100% over the time limit I'd like to achieve. Still, they taste pretty good. As for the roaster, the exterior remained completely cool. Nice!

Check out the video links:

Exterior view (4.2M AVI)

View of beans agitating behind light (2.8M AVI)

Just one photo this time:

I consider this chapter closed. I learned what I needed to know. This was fun!

Update 4

Well, to qualify things a bit, the Fischertechnik chassis and the mug is the closed chapter. My development of radiant roasting for the home goes on. I've obtained needed halogens and high temp silicon, and purchased a cheap 1.5 L carafe whose internal contours seem just about perfect. Eight oz. green looks about right in it, and eight oz. roasted (elsewhere) fits pretty well too.

If I can build a robust enough roaster to relieve my Wearever Popcorn Pumper of its heavy usage, I'll be pleased. The more powerful poppers are becoming scarce, so it'd be nice to mothball it and bring it out just for "nostalgic roasts" and the like.

Meanwhile, my quest for a larger steel vacuum flask continues -- something that'll do a couple kilos. Imagine something like the above form factors, but the size of a five gallon bucket.

In my dreams. ;-)

P.S. - If any readers are HG/DB roasters, consider that given a properly rotating drum of this sort, a heat gun could easily be directed into the mouth of such a unit. I'm working on IR, but I hafta say this thing would be great with a HG. That'd blow the chaff out well, too; I have to figure a way to do that using radiant -- an extra step the HG approach wouldn't require me to engineer. Hmmm . . . ;-)