History here (Google video)

That popper took me through my first serious half-year of home roasting (I had tinkered with a mostly unmodded unit for some months before that). I also engaged in some roasting and brewing experiments. In early 2006 I accepted an invitation to roast and brew at a small farmer's market, and realized we needed two things. First, a larger roaster for use at the market to roast beans for sale. Second, since we Aeropress each cup using an origin selected by the customer, I do 6 to 8 half-pound roasts three days ahead of market day; these sessions needed to be more rigorous.

This page briefly introduces the resulting popper, which has a unique feature worth documenting. This will not provide step-by-step instructions, diagrams, or schematics for the most fundamental mods -- which, frankly, aren't even most excellently taken to their limit (yet) in my popper. Good instructions for basic and advanced mods may be found here. For my part, I'll be following some good advice from others before next year's market season opens -- might even PID the thing.

This is a 1400 Watt Wearever Popcorn Pumper, akin to the Poppery I and therefore far more potent for airflow possibilities than a Poppery II or the Pumper's kid brother, which are also similar to each other (inside, where it counts).

The unit I'm using has a split heater and blower, and I use a Variac (e.g., 10B-1214 ) on the blower -- I don't control the heat directly. The Variac provides a boost of 140 VAC to the blower alone. With the separate power to the heater held constant, the increased airflow results in cooler air to the chamber, which extends the roast and permits lofting more beans. To increase temperature when necessary, blower power is reduced and the slower air absorbs more heat (per unit air) and has more time to impart it to the beans. So long as agitation is kept vigorous, this works well.

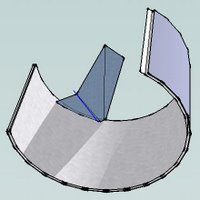

This first photo shows the most important novel feature, something I have't seen in other roasters. I call it an "impeder," and its function is to take the weight of the full column of beans off the beans down near the hot air ports in the bottom of the roasting chamber. As the beans descend, their flow is impeded and the beans beneath the impeder therefore aren't pressed against the bottom of the chamber; they're free to be blown upwards on the uptilt side of the Pyrex glass chamber extension (see further on). Without this impeder in place, attempts to roast 8 to 10 ounces generally result in a stubborn pack of beans intent on hanging around the bottom of the chamber; there's just no circulation.

Obviously not an innovation, but deserving mention here is a thermocouple identical to what I use in my drum roaster (thanks Doug!); my placement in both has yielded very similar roasts in both. The business end of the TC emerges from a route in full contact with the bottom surface of the impeder. The TC appears to be very close to the bottom of the chamber, but it's actually 1.5 inches up. The impeder surface is concave when viewed from the top, tilting to the lower left as shown here. Less apparent is the way the inner end of the metal strip points upward. Actually, I prefer a very different impeder approach but for reasons too ridiculous to recount I didn't implement it. This works fine.

Well OK, call it three innovations. Here's the third (I'll get to the second one a bit further on ;-) This is a ceramic IR emitter, which I generally wire into the same extension cord I use for the heater. Although the unit is only a 150 Watt element, it draws sufficient current in parallel to attenuate the heat of the main element, which helps slow the roast. At the same time, it provides IR heating of the beans when they've lofted significantly high in the Pyrex tube, lending helpful stability to the key late stages of the roast. The simplest way to declare the value of this thing is that it makes a home stretch roast stall almost impossible, even if I'm off on my Variac settings.

Then there's the bread tube -- the second key feature. Search E-bay for corning bake round duo bread and you'll find the right size -- a pair of 3" diameter Pyrex tubes. Sometimes. Other searches will yield many single tubes, but these are all going to be the wrong size. Still, be glad they're only available in doubles; a spare is valuable! This size also fits the Poppery I. The thing is long -- but that's fine, because with 8 ounces of beans they'll fly out anyway once they're past first crack.

I put a steep tilt on the roaster to get a good flow. It's not true that the more you tilt a popper, the more beans you can roast. That's true to a point, but tilt further and things just get weird. My method of tilting -- parking the roaster in a plastic bowl -- helps with roast repeatability, because tilt is definitely an important variable during a roast.

The next photo looks like there's no tilt; actually I tilted the camera. The low side (downflow) is on the left, and beans are spouting upwards on the right. It seems that cameras tend to show few beans in the air, but the agitation at this stage was actually pretty fast.

Here's a roast that's just beyond first crack. Agitation at this point is great -- a good flow. The beans are picking up IR from the ceramic. The tube is providing far better flow than a hurricane lamp chimney. I had reached a limit with that, as seen in the Google video -- a frustrating co-location of the upper slope of the chimney's glass with the upper level of the beans on the down-flow side of the chamber. The tube simply rocks. This is what 8 ounces looks like (well, by now it's under 7):

I suppose I ought to show the exhaust method I employ -- a duct to a window. I poked a hole in the duct to sniff while roasting. Most of the chaff goes out to the yard:

That's it in a nutshell. An impeder, the Pyrex tube, and an IR emitter -- the latter an option, but the first two pretty darned important for the results I've been getting.

[edit] Some images showing impeder and TC placement, roughly. Click to view larger image; note the location of the blue line (which will have to suffice as representing the TC wire).

I'll be editing this page over the winter, I'm sure. Check back by May '07 for sure!

HTH